Founded in 1947 by Bruce and Amy Hodgdon and sons JB and Bob, Hodgdon is now the preferred powder for handloaders and muzzleloader hunters

Multiple sites are now impersonating the Hodgdon Powder Company or our brands like Hodgdon, IMR, Winchester Smokeless Propellants, Accurate Powder or Ramshot.

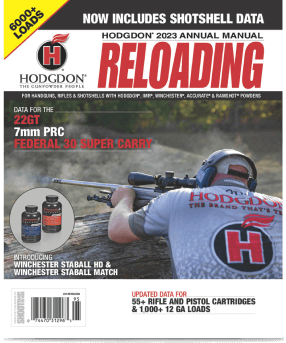

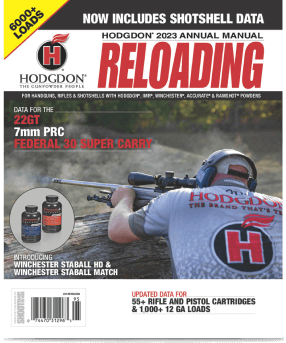

Stay up to date with reloading information, new product alerts, company news and new product release information.

CFE BLK contains our Copper Fouling Eraser ingredient, originally used in military propellant, which greatly deters copper fouling and contributes to longer periods of top accuracy with less barrel cleaning time.

Triple Seven 50/50 pellets are 50-caliber, 50-grain pellets designed for use in 50-caliber, in-line rifles. Triple Seven® Pellets dramatically reduce fouling and reload fast.

Hodgdon Powder Company operates following Biblical principles to honor God. Our mission is to provide quality products and services in a manner which enhances the lives of our employees, families, customers, suppliers, and our communities. In doing so, we deal with integrity and honesty, reflecting that people are more important than dollars, and that our purpose is to bring credit to our Lord Jesus Christ.